-

sales@oilmillmachinery.com -

View Mobile Number - Send SMS

- Send Email

- GST No. 03AAVPG4261E1ZV

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Edible Oil Refinery Plant |

| Voltage | 440V, 380V, 220V |

| Production Capacity | 5 - 30 Ton/day |

| Click to view more | |

Product Details

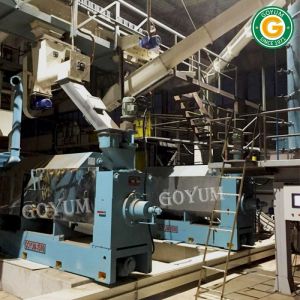

We are manufacturer, exporter & supplier of Cooking / Edible Oil Refinery Plant.

As per the today’s market research it is being concluded that the market demands the refined edible oil with characteristics such as blend flavour and odour, clear appearance, light colour, long shelf life, suitable for frying since the crude oil obtain does contain many harmful factors like free fatty acid, sediments, gums, odoriferous compound and other impurities.

GOYUM with an experience of more than 5 decades in the Edible oil industry have worked unremittingly in more than 60 countries of the world and have developed overall solutions for the Edible oil refinery needs of the customers.

GOYUM provides complete solution for Edible Oil Refinery Plant, capacity to design, build and supply plants from 5 - 30 TPD

Edible Oil Refinery Plant Process :

Degumming Neutralization

- Efficient Removal of hydratable and non-hydratable phosphatide

- Improve physical stability

- Require low utility consumption

- Efficient design

- Less maintenance cost

- Better process

Bleaching

- Remove colouring pigments, traces of gums and metallic impurities

- Improve physical appearance

- Lower Bleaching earth consumption

- Uniform mixing of oil and earth

- Maintenance free Bleacher

- No dead area in Bleacher

- No carryover to Vacuum System

- Lower percentage of oil in Spent Cakes

Dewaxing / Winterization

- Remove small quantity of solid from oil

- Efficient removal of waxes and saturated glycerides.

- Maximum heat transfer area of Crystallizer

- Perfect cooling profile

- Step cooling for complete granulation

Deodorization

- Efficient removal of more volatile component like

- Free fatty acids, minor amount of colouring pigments

- Remove odoriferous compound

- Remove minor amount of colouring pigments

- Maximum heat transfer area

- Lower utility consumption

- Maximum Heat Recovery

- Zero contamination

- Elaborated and efficient design for the removal of fatty acid in Physical type DEO

- Longer shelf life of oil

- Very Low Maintenance

Palm Oil Fractionation

- Larger heat transfer area with regard to the oil charge in the crystallizers.

- Optimal position of the heat exchange surfaces with regard to the impellers and therefore to the oil circulation in the vessel.

- All parts of the processed oil are really driven too close to the heat exchange surfaces.

- The cooling program is accurately followed.

- Granulation by step cooling